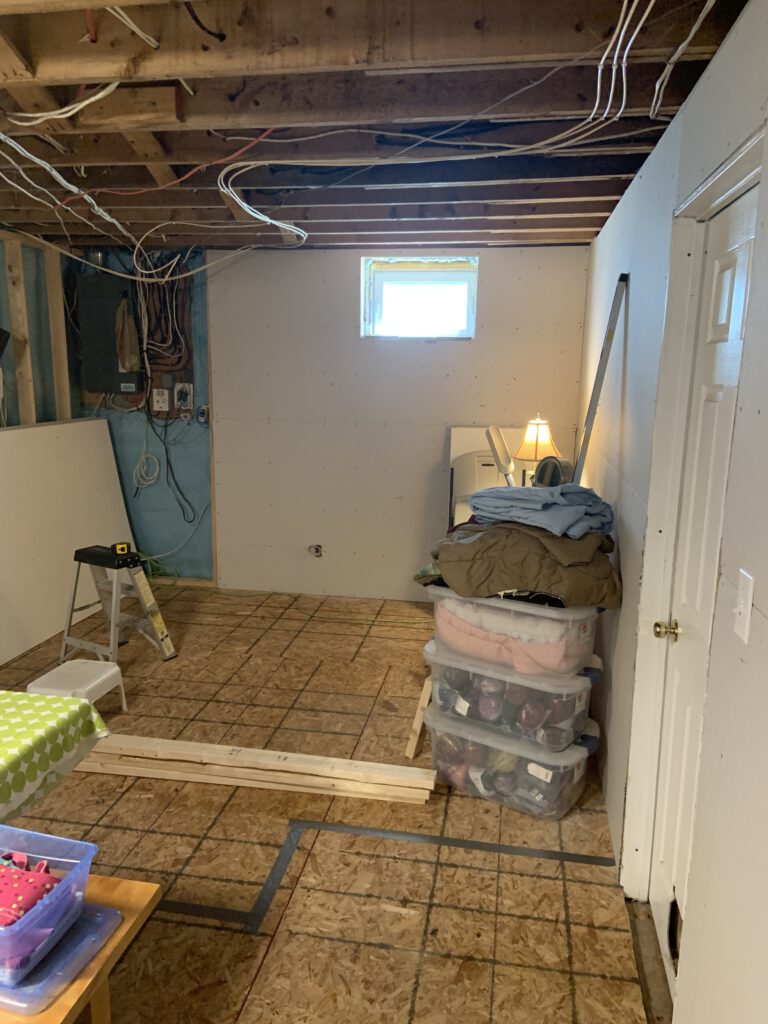

Adding a room in the basement for Emma – everyone will finally have their own room when it’s done! Started roughing in walls. Still a lot to do. We will need a new electrical panel installed – we’ve needed it for a long time, but it will be in this room, so want to get it done before sealing the walls up. Also need to cut a hole in the foundation for new, larger window to allow for egress as well as let some more natural light in. One step at a time.

Category Archives: The Fack Ranch

Backyard Movie Night

Had the idea to set up the Mac outside and stream a movie for the fam. Was fun – makes me think I should find a bigger screen tv or projector and have some CABC ‘bike-in’ movie nights. The feature this evening? The Triplets of Belleville. Very good.

Carry Wood

My 3 cords of firewood were delivered and I set about stacking it to dry. I worked a little each day, in chunks. Partly because it was a good mental exercise break, but also because the heat was pretty serious at times.

There’s been volumes written about the merits of manual labor – in case you haven’t read any of it, the TLDR is that it’s good for you.

I most often stack my wood in silence, choosing to enjoy and absorb the sounds around me and the voices in my head. On one particular occasion, I decided to listen to some music via my Air Pods. It was different.

I was stacking my wood like usual, thinking about all the other things I had to do, what was currently wrong and all the other things that had to be sorted as my playlist churned out in the Air Pods. Gary Clark Jr’s live version of ‘When My Train Pulls In’ came on. I thought how amazing it was that I was walking back and forth in the middle of my yard, in the woods – in the middle of nowhere essentially – on a nice overcast day with a slight breeze keeping the bugs down and at the same time I was being steamrolled by the music this man was making – or channelling – in another time and another place.

As the solo in the song peaked, I realized that none of that stuff I was thinking about prior really mattered. That, indeed, there was no place I could be other than where I was right at that moment, doing what I was doing, because everything had led to that moment – there was no way things could be otherwise. There was no way I could be anywhere else, doing anything else, there, or in the Universe at large. Nothing could have changed the things that were wrong, or sorted what needed sorting, or finished what needed doing. I was supposed to be right where I was. So everything was alright – and couldn’t get alrighter.

That was my satori moment with Zen master Gary Clark Jr.